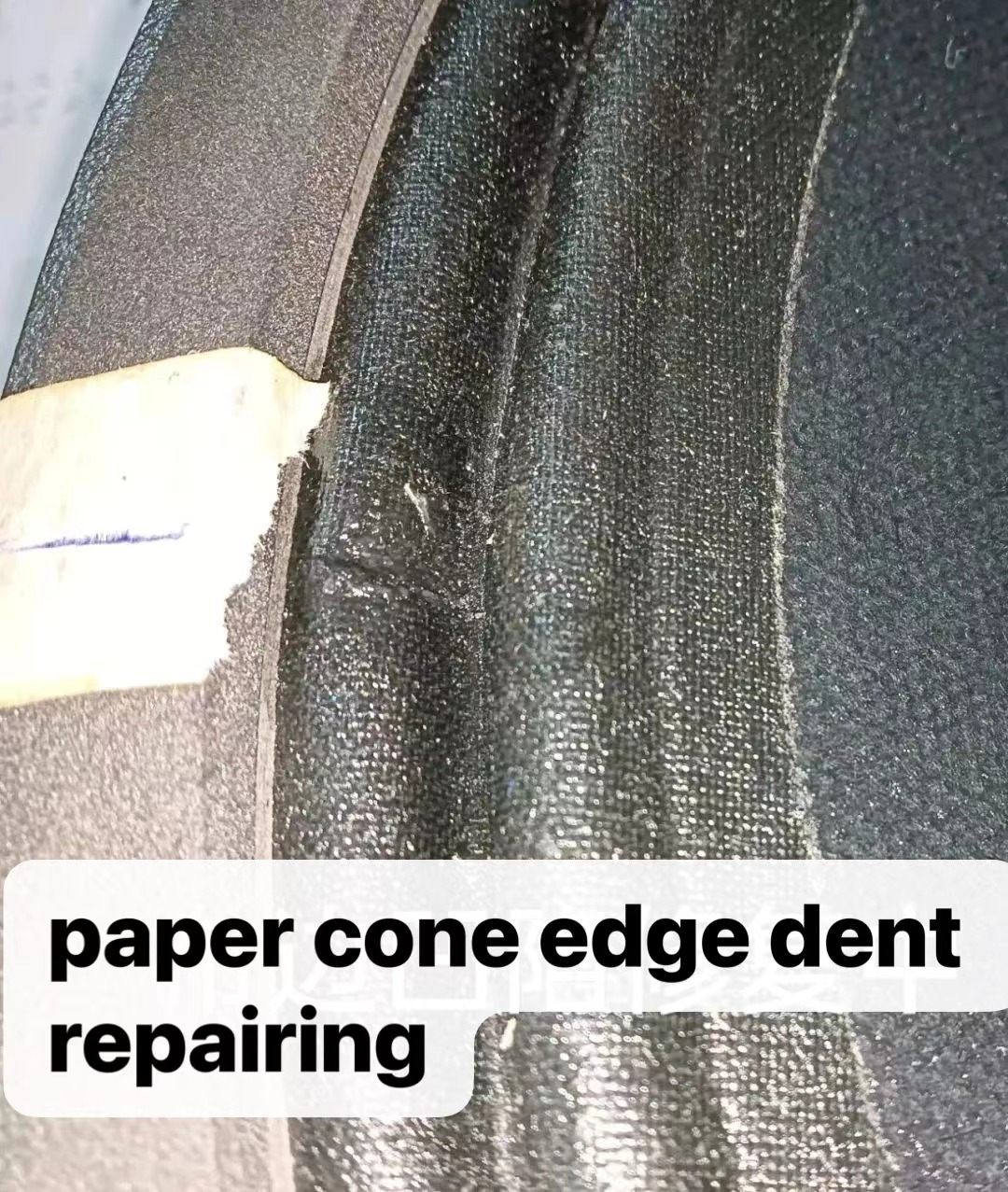

During the production, storage, and use of speakers, due to various factors, the surface is accidental, but from time to time we can see the problem of partial “collapse” or “depression” of the edge of the speaker. Although the reasons for this are difficult to find out, they can also be divided into the following aspects.

1. Due to factors such as uneven cloth texture, uneven sizing, and uneven heating during the processing process, although the appearance of the edge after setting is acceptable when it is delivered, after a long time, due to the “annealing” effect, causing the stress to be released, resulting in a non-uniform shrinkage.

2. After the speaker is produced, it is caused by external force extrusion during storage.

3. The speaker is caused by uneven stress or material aging during use.

If you want to carefully analyze the reasons for the creases on the edge, it may make the problem more complicated. As shown in the picture above, the reason why it is difficult to judge the crease is that for this mark, there is force from the inside to the outside and also from the outside to the inside. The sag of this speaker was discovered by the user when the speaker was opened, and then hoped to recover naturally after a long period of storage, but it didn’t work.

But regardless of what caused it, we just tried to fix it as best we could, returning it to its original shape and elasticity.

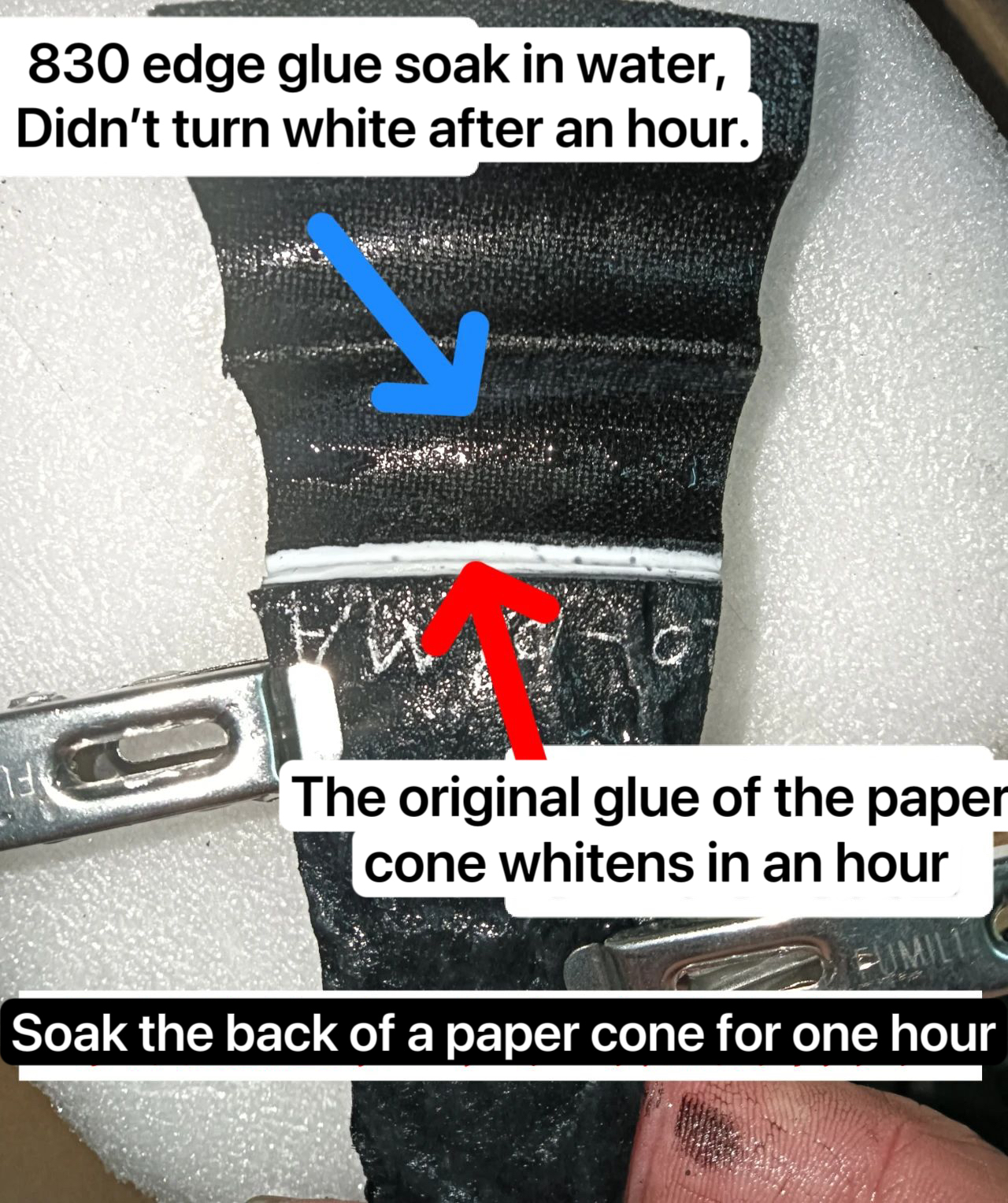

The biggest problem in repairing the speaker is that we don’t know what kind of material the damping rubber material is coated on the edge of the cloth, such as polarity and nonpolarity, permeability or swelling, etc. for chemical materials; if we use a simple Appearance dissolution analysis method, whether the blister is swollen (white) and easy to fall off, or the organic solvent bubble-soluble type, etc. If these are not clarified, it will become a difficult design and repair process, but if it is clarified, even the manufacturer may not have a solution; in addition, especially for different foreign speaker manufacturers, the selvage used by each of them may be Damping glue is not the same.

In the picture below, the “invulnerable” selvage glue and ketone glue. You might as well try to drop a few drops of toluene on the bombs and cloth edges of the speakers and see.

But regardless of the cause of the edge dent here, we just try to repair it as much as possible, returning it to its original shape and elasticity as much as possible.

But regardless of the cause of the edge dent here, we just try to repair it as much as possible, returning it to its original shape and elasticity as much as possible.

Although knowing the cause of the problem will be of great help to the selection of repairing techniques and materials, the reality often does not have such conditions. Therefore, according to the actual situation, the repairing materials used here are Restorative agent JM-1.

The restorative material is liquid in appearance and takes effect quickly. However, the “skill” of repairing various selvedge depressions still needs in-depth observation. But some “traces” that have destroyed the fibrous tissue are powerless.

The restorative material is liquid in appearance and takes effect quickly. However, the “skill” of repairing various selvedge depressions still needs in-depth observation. But some “traces” that have destroyed the fibrous tissue are powerless.

Although the toxicity of this product is much lower than that of toluene, but it has a smell, the operator is required to use waterproof gloves, protective masks, work clothes, good ventilation conditions and other labor protection measures for construction.