Your Professional Subwoofer Manufacturer

Whether it’s the polypropylene woofer cone, engineered for peak efficiency,

these subwoofers consistently deliver outstanding performance that exceeds your expectations.

Your Subwoofer Brand Customization Expert

MRaudio is a subwoofer manufacturer in China that provides 6.5 inch, 8 inch, 10 inch, 12 inch, 15 inch, 18 inch and other sizes, adapting to different models and space constraints to ensure a perfect installation. We actively develop new technologies, provide customized speaker models, and continuously improve product performance.

MR Audio Your Exclusive Subwoofer Manufacturer

A Professional Team For Your Subwoofer Customization

MR Audio has 20 years of OEM production experience and focuses on car audio production. A complete set of speaker automated assembly lines, with a production workshop of more than 8,000 square meters.

We are customer-centric and committed to continuously improving product performance and reliability to meet different musical tastes and listening needs.

Car Subwoofer Kits & Components

We understand the local market needs and provide complete speaker kits and various components to help you improve sales in the local market, attract more customers, and promote the growth of your business.

Car Subwoofers & Accessories

We provide matching speaker accessories and peripheral products, stable raw material suppliers, make the speaker sound consistent, and provide one-stop shopping convenience, so customers do not need to look for the required audio components everywhere.

Why Choose MR Audio

- Workshop

- Exhibition Display

- Certificate Display

More Recommended Products from MR Audio

MR audio is your time-tested Subwoofer supplier

Chuck spends a month in the Americas every winter to visit some old customers and learn about the products in the local market.

Do you know? In Latin America, especially the Caribbean coast, Car audio is very crazy, and people’s love for music comes from the heart. They also have very high requirements for the power of the car audio, especially in the power of the subwoofer, that is, enough power.

When Chuck visited a Panamanian customer, They talked about this. Many big-brand European subwoofers were sold to their market, and the power did not meet the requirements. So every time they buy these subwoofers, they have to do a new process, brushing more glue on the voice coil, spider, and paper cones to make these materials can carry more power. The customer told Chuck at that time that if you can solve the power problem of these subwoofers, then our subwoofers can quickly open up the market in the entire Latin American market, and I will place a big order for you.

Knowing this information, after Chuck returned to China, he immediately convened a meeting with engineers from the R&D department to study how to increase the power of the subwoofer.

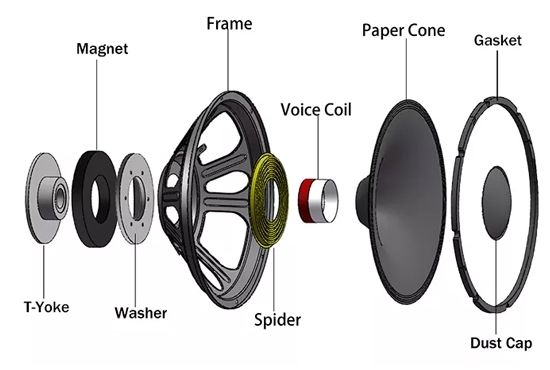

The voice coil is the heart of a loudspeaker. Many times when the subwoofer is working, the voice coil is burned first. So let’s solve the voice coil problem first.

First, we change the material of the voice coil bobbin to a special glass fiber material. Its temperature resistance can reach 220°, which is the highest temperature-resistant voice coil bobbin material. Next is the voice coil line problem. Many voice coils will separate from the bobbin at high temperatures. This is glue. The temperature resistance is not enough. We replaced it with glue imported from Japan. After making these changes, we made a subwoofer with the new material and then went to do a power test.

After 6 hours, we found that the voice coil of the subwoofer had bottomed. After taking it off, it was analyzed that the sound of the subwoofer slowly began to soften under high power for a long time. The amplitude of the subwoofer became larger, and the voice coil was hit. The phenomenon of T yoke. We changed the spider from 2 layers to 4 layers, the material was changed to NOMEX material, and the surface was also brushed with a layer of damping glue, which made the fatigue resistance of the entire voice coil much better.

Do the sample test again. After 16 hours, the cone of the subwoofer cracked and gradually became larger. It seems that the strength of the cone is problematic. It cannot withstand high power for such a long time. We must strengthen this toughness of the cone, some engineers proposed to add glass fiber materials to improve this problem. After repeated communication with the paper cone factory, 30 days later, the factory gave us samples of paper cones that met the requirements. Not only did the new paper cones become tougher, the rigidity of the paper cones also became better, and the bass effect came out. Will be more powerful.

The subwoofer was made again for testing, and the 4000-watt power passed the 24-hour test.

The customer received the sample one month later. After repeated tests, they are very satisfied with this subwoofer product. The bass is strong and powerful, and the power has reached the market requirements. They are very confident that this product will be sold in their market immediately. Placed a big order to us.

It took a total of 4 months for this subwoofer product from development to completion. We have been constantly testing and adjusting. Engineers have improved every detail and made adjustments in advance to some hidden dangers, and finally made a decision. This product is very appreciated by customers. The success of every product lies in continuous analysis and improvement.

MR Audio-Your Reliable Subwoofer Manufacturer in China

If you’re looking for the best subwoofer manufacturer to support your business, MR AUDIO is the right place to come! We have over 20 years of OEM experience and can provide you with a customized solution based on your specifications.

MR AUDIO is committed to providing you with the best subwoofer products based on our technology innovations and scientific management. MR AUDIO is your reliable subwoofer manufacturer, offering the best car video and car audio for you.

Our company has two decades of subwoofer development and customization experience. Being the top subwoofer manufacturer, we utilize professional production technology, advanced equipment, and rich tuning experiences to produce high-quality subwoofers for your car.

Our skilled and professional design engineers can provide you with a user-friendly subwoofer combined with unmatched reliability and advanced performance features. MR AUDIO can design and develop your subwoofer per your personalized customization.

MR AUDIO is the most significant subwoofer manufacturer in China, offering competitive prices, professional after-sale services, high-quality, and on-time delivery for your orders. All you need for your subwoofers are here in MR AUDIO. You can get at lower MOQ with OEM services.

If you’re a distributor or supplier that needs to import a high-quality subwoofer, MR AUDIO is the top subwoofer manufacturer you can trust! We dedicate ourselves to continue serving our customers and getting the best customer satisfaction.

For more information about our products and services, please don’t hesitate to contact us now!

Car subwoofers have many advantages, including powerful, responsive bass that sounds full and crisp. Sound clarity has also improved, and the in-car music system sounds even better than before, thanks to its flat response and the ability to clearly reproduce all sounds in the frequency spectrum.

Another thing is that car subwoofers can be a good buy for music lovers looking for deep bass from their sound system, regardless of the genre being played. Designed specifically for use in vehicles, these powerful speakers can produce the booming sound you want without breaking

Subwoofers generally come in two types: active and passive subwoofers

Active subwoofer: it is to point to box interior to contain power amplifier subwoofer, the volume is more cabinet commonly, install easily

Because the soundbox interior brings an amplifier, need not add an amplifier so, connect the sound source directly but push. But usually, the output power is relatively small, the musical expression is not very strong.

Passive subwoofer: it refers to the subwoofer that only contains a speaker unit and frequency divider inside the box body and does not contain a power amplifier. Large output power, strong low-frequency signal output, strong musical performance. But it’s big, it’s bulky, it takes up a lot of space.

The power amplifier and subwoofer must be perfectly matched, and they must be matched in impedance, power and frequency to ensure the safe operation of the equipment and fully explore the maximum potential.

Impedance matching, each speaker has an approximate average impedance, this average impedance must be within the range of the amplifier can withstand.

Power matching to ensure that the continuous output power of the subwoofer car amplifier is more than 2 times of the continuous output power of the subwoofer.

Frequency matching, car power amplifier is usually divided into full frequency power amplifier and subwoofer special power amplifier, do not try to use the full frequency power amplifier to promote the subwoofer, so completely can not achieve the desired effect, must use a special subwoofer power amplifier.

Subwoofers are becoming increasingly popular among musicians, with their super-bass melodies that make music more dynamic and aural when mounted in a car. Subwoofers are mainly thin subwoofers and tail box subwoofers. But not every suits him, go choosing according to the demand of oneself, ultra-thin subwoofer volume is smaller, do not take up a space how, can very good concealed type installation, install below seat commonly. The box subwoofer is usually installed in the tail box, which is better than the ultra-thin subwoofer, but it is large and takes up a lot of space.

Subwoofer paper cone materials are mainly these kinds

1, paper cone: good timbre performance, high sensitivity

2. Polypropylene cone: low distortion, good performance of all kinds of music

3. Metal cone: instant explosive force, suitable for dynamic music

4. Woven fiber cone: wide frequency response range, suitable for music lovers who like strong bass

All cone materials have a unique effect on speaker sound quality. For subwoofers, the cone material you choose will have a significant impact on sound quality. There are three types of cones: paper, polypropylene, and Kevlar. Each fabric has its own elasticity and resonance frequency. In other words, each produces its own sound.

Dual voice coils are creating a sensation in the subwoofer market. These improve performance and stability but make it more difficult to tune the subwoofer for optimal performance. The dual voice coil is a common change in subwoofers. More power can be drawn from the amplifier by doubling the number of voice coils. This increases resistance and reduces inductance, allowing for higher peak currents and stronger magnetic fields.

The working process of a car subwoofer is to produce low frequencies. This is done using an amplifying system with a digital signal processor, speakers, and amplifier. It receives a signal from the source and sends it to the speaker. The speaker converts this electrical energy into sound at its resonant frequency. Waves vibrate air particles, which produce sound waves.

The subwoofer box is the enclosure that houses the woofers and helps to project sound. The process of making the wooden box of the subwoofer includes two major steps: cutting and assembling. The first step is about preparing the wood by cutting it to the proportion that you wanted. The second step is about assembling all of the pieces, such as gluing and nailing, to create a fully functional sturdy box.