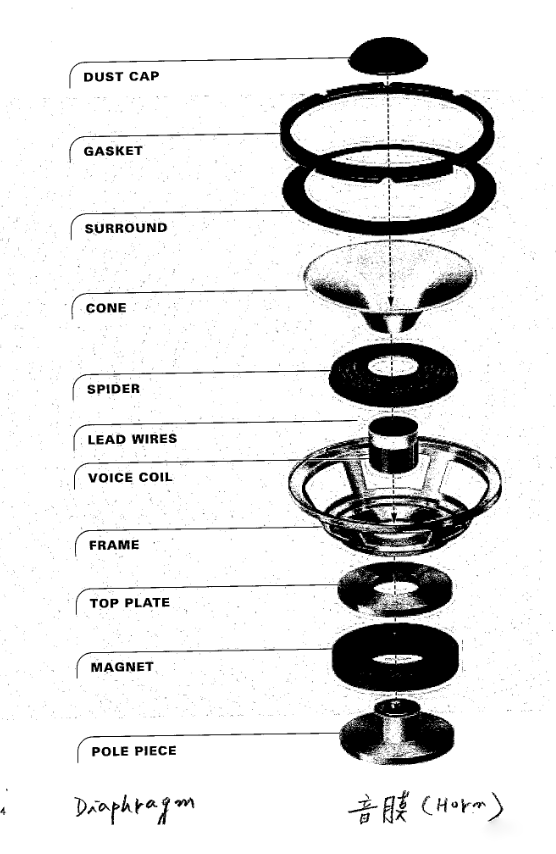

1. Fold the ring and position the drum paper (diaphragm, paper cone) together with the elastic wave for radial movement. The material of the folding ring generally includes rubber, cloth base and adhesive paper, etc. The softness, hardness and flexibility of the folding ring directly affect the linearity of the drum paper in the entire movement, and affect the performance curve of the speaker within the entire nominal power.

2. Drum paper is the main sound-producing component of the horn. The material is mainly pulp plus other materials. In recent years, a variety of materials with different properties have entered, including polypropylene, carbon fiber, titanium metal, etc., and even diamond. But the mainstream is still pulp. On the one hand, it is cheap, and on the other hand, it is easy to make the complex curved surface required for the speaker diaphragm.

3.T iron, plywood. The material is soft iron, that is, pure iron, also called electrical iron. Its main characteristic is magnetic conductivity, but there is no residual magnetism. Even after the magnetic field disappears, its magnetism disappears immediately. The purity and quality of this iron directly affect the efficiency of the speaker, non-linear distortion and other important parameters, among which the thickness of the plywood affects the stroke of the speaker. The T-iron plywood of long-stroke speakers is particularly thick, which means that parallel and uniform magnetic lines of force can be cut throughout the entire stroke of the voice coil. The smaller the gap between the splint and the T-iron center column, the smaller the power required to move the voice coil and the higher the efficiency of the speaker. Therefore, magnetic fluid-type speakers inject magnetic liquid between the T-iron and the splint, which is equivalent to shrinking them. On the other hand, the distance between them also quickly takes away the heat of the voice coil, improving the power tolerance of the speaker.

4. Magnetic steel is generally called magnet or permanent magnet. The name of magnetic steel is more accurate. There is no magnetism before the speaker is assembled. After it is glued to the T-iron plywood with adhesive, it is magnetized on the magnetizer. The final residual magnetism is the magnetism of the magnet steel. The amount of this residual magnetism is the magnetic size of the magnet steel. According to Faraday’s law of electromagnetic induction, the greater the magnetic flux, the greater the force of a certain current moving in the magnetic field. Therefore, in order to improve the power of the speaker, many strong magnetic materials, such as rubidium iron boron, are now used.

5. The voice coil is generally made of flat self-adhesive copper enameled wire. It is a very contradictory component. In order to increase the current (increase power), the wire diameter must be increased. The larger the wire diameter, the larger the magnetic gap required. , when the magnetic gap is large, the power efficiency decreases, so we can only take the middle value in the contradiction. Voice coils are generally wound in two layers, and wires cannot be drawn out in single-layer windings. In order to increase the magnetic field formed by the current without changing the size of the magnetic gap, the diameter of the voice coil can only be increased. So there is a large voice coil and long excursion claimed by HiFi speakers. The voice coil is wound on a paper frame. Some high-power speaker frames are made of aluminum foil, so-called aluminum voice coils. The voice coil is still copper, but the frame is aluminum!

6. Shields, anti-magnetic leakage components, are generally made of soft iron. However, some low-priced speakers are made of carbon steel or ordinary iron plates in order to reduce costs, and the anti-magnetic leakage effect is greatly reduced. In fact, this form of anti-magnetic leakage has been Although the effect is not good, there is still a small amount of magnetic leakage. In the strict requirements of anti-magnetic leakage, the speaker magnet is installed on the center column of the T iron, so that the entire magnetic field line system is closed and there is no static magnetic leakage at all. Of course, this requires a very large magnetic flux of the magnet, high processing requirements, and of course high cost.

7. The lead wire is composed of braided copper wire and cotton wire. It is mainly used to maintain the normal connection between the voice coil and external wires in the vibration environment of the speaker.

Basin Stand

The speaker frame mainly supports the stable connection between the drum paper and other components of the speaker. Its rigidity has a great impact on the sound quality. Generally, speakers are stamped from galvanized steel plates, with curved facade reinforcements or embossed reinforcements formed on the edges. Why do we need to press the reinforcement, because thinner materials can be used due to cost considerations. This is certainly not the first choice for high-quality speakers.

Nowadays, speakers with high requirements usually use cast aluminum basin frame, which is light weight, good rigidity and easy to be processed into the required shape. Since speakers are generally installed vertically, due to the influence of the earth’s gravity, especially speakers with large magnets, the rear weight is very heavy, so one side of the basin frame will be specially reinforced to offset the deformation caused by the installation method.

Overseas The best speakers are installed with upper and lower sides, and they cannot be installed at any 360 degrees just because they are round. Domestic HiFi manufacturers rarely pay attention to this problem, and foreign top-quality speakers regard this as a trade secret – this is why the same domestic manufacturers that use Sias Odis speakers cannot make speakers with the same good sound (of course, the factors are not only this point). On the other hand, I have seen audiophile-made speakers that use a board as a support behind the speaker.

I have also tried it, but I did not hear any changes in the sound quality. Maybe other factors have a greater impact. There are still basin frames made of engineering plastics, but the rigidity is still not good enough. I don’t think they will become mainstream in a short time.

In addition to its supporting role, the midrange speaker basin frame is also a small speaker box, which is closed. For good-quality speakers, sound-absorbing cotton will be placed inside this small speaker box to improve the sound quality.

Dust Cap

The materials are various and the shapes are also various. Why is this? Because in addition to the dust-proof effect, the beauty of the speaker also depends on its design. Among them, the oversized dust cover represented by Danish Dynaudio has become a part of the diaphragm sound generation and can be described as the ultimate representative.

There is also the HiVi’s soft dust cover, which solves the problem of being unable to come up when someone presses it. As for the improvement of sound quality, I disagree. Among them, the HiVi 10″ carbon plastic polypropylene speaker abandoned the soft dust cover because the dust cover would be sucked in at high power, and only used soft ones for diameters below 8″.

It is the earliest gauze dust cover that is the most scientific. The air resistance is very small and can prevent dust. It is not used as part of the sound generation and will not affect the frequency response curve of the paper cone that has been designed according to the surface equation. Then there is the bullet head.

In foreign countries, the brand is represented by Sias. Around 1997, it suddenly became popular in China. As for how much it can improve the sound quality, it is a matter of opinion and wisdom. One thing is certain, this smooth curved surface will definitely form a sound focus somewhere in the space. Sound focus is always something that a good playback system should avoid, just like how to avoid stray light spots in photography technology.