This MR Audio blog post will go over the significance of suspensions and magnets.

A cone speaker in cross-section

Peripheral suspension

Car woofer with a noticeable suspension

The speaker’s frame is held together by a suspension, which can be more or less flexible. Its primary function is to keep the diaphragm in place while allowing it to move freely. It also aids in preventing diaphragm displacement and absorbing resulting resonances. Peripheral suspensions can have a variety of profiles and materials. The first prototypes were made of chamois leather, fabric, or paper. They were gradually replaced, however, by rubber and synthetic foams. The suspension and diaphragm can also be made as a single piece by treating the latter’s external frame with special molding and varnishing techniques.

The suspension material must be chosen in accordance with the density of the diaphragm and the frequency range of the speaker; it must allow the required displacement in this range while remaining as neutral as possible. The most neutral materials, however, aren’t always the most rigid, and it’s not uncommon for the suspension to degrade before the diaphragm. As a result of the contradictions of having enough flexibility, acoustic neutrality, a long-lasting and quality performance… manufacturers must once again make a compromise.

Spider

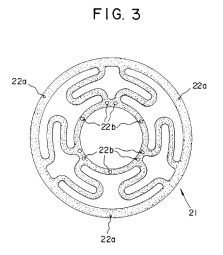

A spider mold – the highlighted points are the resin injection points. [source: US patent US6144753A – Pioneer 1997]

The suspension is insufficient to keep the speaker’s mobile parts (voice coil and diaphragm) in place. If you want the movement to be in a single axis, or if you want to avoid any movement that causes non-linear distortion, you’ll need something to keep the voice coil in place. Despite the narrowness (a couple of millimeters) of the air gap between the pole pieces where the coil sits, the distance between the voice coil and the magnet must always be the same, and it must never come into contact with it.

Generic spider – the most common shape currently used

This suspension is typically in the form of a disk that is attached to the voice coil support on one side and the frame on the other. This element gets its name from its round shape and leg-like design, which resembles a spider, though most speaker spiders no longer resemble a real spider. They are made of a stiffening resin-impregnated fabric and frequently have a corrugated shape that promotes controlled damping. Spiders must be manufactured with extreme care to avoid encouraging movement in any one direction and to provide a uniform movement of the voice coil. A trade-off must be made between good rigidity, which ensures that the voice coil stays in place, and great flexibility, which allows it to move freely.

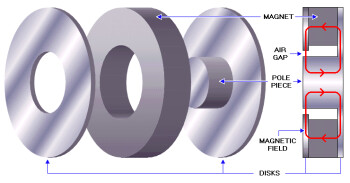

Magnetic circuit

The intensity of the magnetic field in which the voice coil moves is critical to the speaker’s sensitivity. The magnetic field’s quality is determined by the magnet’s characteristics and the pole pieces’ proper assembly. These items are made of soft iron or a magnetic material. They are used to align the magnet’s poles at the same level as the air gap, leaving just enough space for the voice coil to move within the magnetic field. The stronger the magnetic field, the narrower the gap, but the less room the voice coil has to dissipate the accumulated heat.

Magnets can be made of a variety of materials. Manufacturers select them based on their inherent qualities. They must consider the intensity of the magnetic field, the available space, how their magnetic properties hold up over time and under extreme conditions, and, most importantly, the production costs. Since cobalt prices began to rise in the 1970s, it has been gradually replaced by ferrite and neodymium alloys.

A typical magnetic circuit diagram (Author: Stephen Swenson)

The magnet can be mounted at the center of the voice coil or at the edges, around the voice coil, depending on the type of magnet and the size of the speaker. The center-mounting technique ensures fewer magnetic leaks, but it makes cooling the voice coil more difficult (the magnet is pierced so that air can flow through it). This type of mounting is more suitable for cobalt magnets, which helps to explain the current dominance of peripheral mounting, which is better suited for ferrite and neodymium magnets.

Following this brief (by no means exhaustive!) review of some of the most important issues affecting the design of electrodynamic cone loudspeakers, the following article will discuss dome and compression chamber loudspeakers.